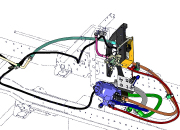

FSB 1500/2600

- Modular system allows extensive combinations of various components

- Hydraulically swiveling right / left:

- maximum tilt ±32°

- Flushing beam pipe and linkage made of stainless steel

- Continuously telescopic via chain drive:

- 1100 mm displacement, right or left

- All parts of the base frame and attachments are powder-coated

- Integrated collision protection right / left up to 30°

- Support stand as standard

Options:

- Electrically adjustable / switchable fan jet nozzles (frog-mouth)***

- Side nozzles right / left**

- Vertical spray bar**

- Electronically switchable high-pressure underfloor nozzle**

- Electronically switchable middle section**

- Electronic collision protection on side displacement**

- Integrated lifting device

- Mechanical swivel angle adjustment

- Hydraulically driven medium-/high-pressure pump

- Marker lights

- Reflector plate with warning markings

- Automatic reel (mechanical)

- Hydraulic reel (radio-controlled)

- Splash guard, reducing spray mist

- Other colors on request

Technical data:

- Weight: approx. 50 kg (basic equipment)

- Working width:

- approx. 1.5 m to 2.6 m (straight)

- approx. 1.1 m to 2.1 m (tilted 32°)

- Water capacity:

- Medium pressure: 200 / 300 l/min at 20 bar; 170 l/min at 50 bar

- High pressure on request

- Swivel angle: 32° right / left

- Color: Anthracite gray RAL 7016, Municipal orange RAL 2011

- L x W x H: approx. 550 x 1500 x 400 mm

Image(s) similar, show special equipment!

** FMC / *** FMC and EASY Control mandatory

![[Translate to english:] Sickle mowers](/fileadmin/_processed_/8/c/csm_vorschaubild_FFS_3282ae4150.jpg)

![[Translate to english:] Tank systems](/fileadmin/_processed_/6/6/csm_fts_vorschaubild_991af2d481.jpg)

![[Translate to english:] Watering arm](/fileadmin/_processed_/5/c/csm_FGA-vorschaubild_4b6f0c9396.jpg)

![[Translate to english:] Washing boom](/fileadmin/_processed_/e/3/csm_FSB_vorschaubild_201a2a4cfe.jpg)

![[Translate to english:] Scrubbing Deck Brush](/fileadmin/_processed_/8/c/csm_FSD_vorschaubild__2dd8e0f1de.jpg)

![[Translate to english:] Washing brush](/fileadmin/_processed_/3/3/csm_FWB_vorschaubild_ec78bb85fc.jpg)

![[Translate to english:] Sewer flusher](/fileadmin/_processed_/6/9/csm_vorschaubild_kanalspueler_2376f176a9.jpg)

![[Translate to english:] Front sweeping machines](/fileadmin/_processed_/2/e/csm_FKM_vorschaubild_baa60a82de.jpg)

![[Translate to english:] Weed brush](/fileadmin/_processed_/7/3/csm_fwk_vorschaubild_737717a7b3.jpg)

![[Translate to english:] Hot water system](/fileadmin/_processed_/5/2/csm_ftskombi_vorschaubild_3b0e8d5e7f.jpg)

![[Translate to english:] Weed brush](/fileadmin/_processed_/c/7/csm_FUV-vorschaubild_34df2a5752.jpg)

![[Translate to english:] foliage & waste aspiration](/fileadmin/_processed_/e/3/csm_FLAS_vorschaubild_675f23f59a.jpg)

![[Translate to english:] Container systems](/fileadmin/_processed_/c/f/csm_container_fsc_58e2818af0.jpg)

![[Translate to english:] Snow ploughs / full mouldboard foldable plough](/fileadmin/_processed_/8/5/csm_FRS-vorschaubild_2_a6af3349f6.jpg)

![[Translate to english:] Spring flap plough](/fileadmin/_processed_/9/5/csm_FRS-vorschaubild_191c662338.jpg)

![[Translate to english:] Wedge-shaped plough](/fileadmin/_processed_/6/0/csm_webseite-vorschaubild_eaa02f6fd8.jpg)

![[Translate to english:] Clearing / Sweeping Unit](/fileadmin/_processed_/e/2/csm_FRK_vorschaubild_dd6912ef49.jpg)

![[Translate to english:] Brine sprayer](/fileadmin/_processed_/3/7/csm_FSSA_Vorschau_531cbad5c2.jpg)

![[Translate to english:] Attachment spreader](/fileadmin/_processed_/d/c/csm_FWS-vorschaubild_de11754d00.jpg)

![[Translate to english:] Chassis-mounted spreader](/fileadmin/_processed_/b/e/csm_FSS_vorschaubild_6c6dd9041e.jpg)

![[Translate to english:] Brine mixing plant](/fileadmin/_processed_/1/1/csm_FSMA_vorschaubild_e32f10e853.jpg)

![[Translate to english:] Universal front lift](/fileadmin/_processed_/5/8/csm_FUF_vorschaubild_9e5a112cfd.jpg)

![[Translate to english:] Rear blower](/fileadmin/_processed_/7/4/csm_FHG_menue_6cdd000772.jpg)

![[Translate to english:] Adapter plates](/fileadmin/_processed_/4/7/csm_Adabterplatte_5c2ac30b03.jpg)

![[Translate to english:] Control panels](/fileadmin/_processed_/a/1/csm_Bedienpulte_79c6d27fcc.jpg)

![[Translate to english:] Lamp holder](/fileadmin/_processed_/e/3/csm_Lampentraeger_01_144be172f2.jpg)

![[Translate to english:] Data collection](/fileadmin/_processed_/5/d/csm_Datenerfassung_2c1bbc88e1.jpg)